Panel beating, or paintless dent repair (PDR), is a skilled trade that manipulates metal to restore damaged car panels without replacement, saving cost and resources. Techniques like hammering and stretching remove dents while preserving paint job and vehicle aesthetic appeal. This eco-friendly method extends car lifespans, conserves materials, and promotes a circular economy in automotive restoration practices.

Panel beating is a skilled technique that offers an alternative solution to full panel replacement, proving cost-effective and environmentally friendly. This ancient craft involves reshaping and repairing damaged car panels without replacing the entire section, reducing waste and material costs. By understanding the various panel beating techniques and their benefits, motorists can make informed choices, opting for more sustainable repair methods. This article explores these advantages in detail.

- Understanding Panel Beating Techniques

- Cost-Effective Solutions it Offers

- Benefits for Sustainability and Waste Reduction

Understanding Panel Beating Techniques

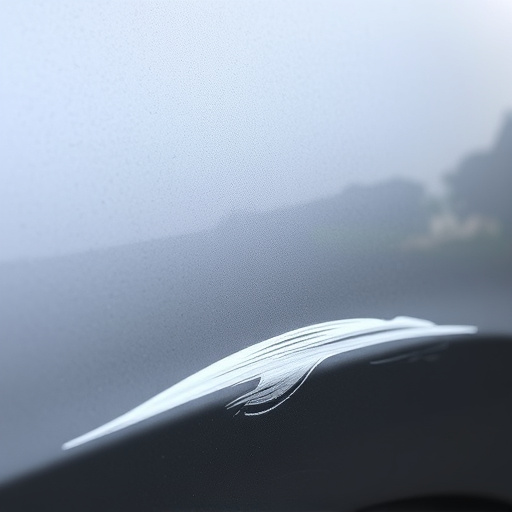

Panel beating is a skilled trade that involves manipulating and reshaping metal to restore damaged car panels, aiming to avoid full panel replacement. This artful process includes techniques such as hammering, stretching, and pressing, which can effectively remove dents and dings, returning the panel to its original shape and integrity. The technique is also known for its ability to preserve the original paint job, making it a preferred method for those seeking high-quality automotive restoration without the costs associated with complete panel replacement.

In the realm of car paint repair, panel beating excels as a non-invasive approach, known as paintless dent repair (PDR), which has become increasingly popular among car owners and automotive professionals. This method leverages specialized tools and techniques to correct minor damage while maintaining the vehicle’s aesthetic appeal. By expertly applying these panel beating techniques, skilled technicians can restore cars to their pre-damaged condition, showcasing the versatility and effectiveness of this craft in modern automotive restoration practices.

Cost-Effective Solutions it Offers

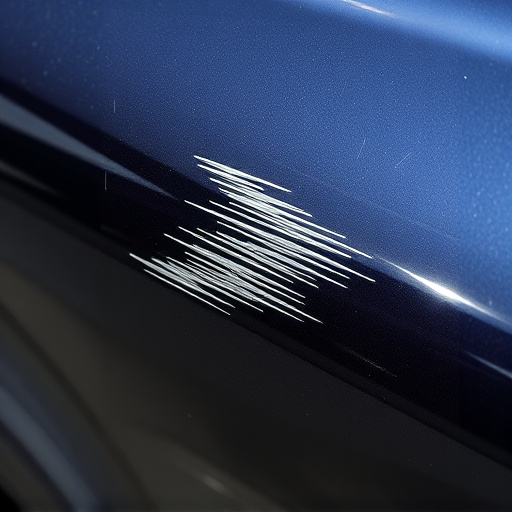

Panel beating offers a cost-effective solution for automotive body shops and car owners alike. By expertly mending damaged panels instead of outright replacing them, significant savings can be realized. This not only reduces the financial burden but also minimizes waste, as recycled materials from the original panel can often be used in the repair process.

Furthermore, panel beating techniques allow for precise restoration of the vehicle’s aesthetic appeal. Skilled technicians can match the original paint and finish flawlessly, ensuring that the repaired area blends seamlessly with the rest of the car. This level of craftsmanship not only preserves the car’s value but also extends its lifespan, making it a preferred option over complete panel replacement in many cases, especially for minor dents and dings.

Benefits for Sustainability and Waste Reduction

The practice of panel beating offers a sustainable solution to auto collision centers and vehicle body repair workshops. Instead of discarding damaged panels and replacing entire bodies, skilled technicians can expertly repair and reshape metal, extending the lifespan of vehicles. This approach significantly reduces waste, which is a growing concern in the automotive industry. By minimizing scrap materials and energy consumption associated with panel replacement, panel beating contributes to a greener environment.

Furthermore, it plays a crucial role in resource conservation. Many components of a vehicle are reusable and can be salvaged from damaged cars, promoting a circular economy. This process not only benefits the planet but also provides an economic advantage by lowering the cost of repairs for both workshops and vehicle owners, making it a practical and eco-friendly choice in collision damage repair.

Panel beating is a highly effective, cost-efficient method that significantly reduces the need for full panel replacement. By utilizing specialized techniques, this process not only restores damaged panels to their original condition but also offers substantial financial and environmental benefits. It is an eco-friendly approach that minimizes waste, promotes sustainability, and provides a viable solution for both vehicle owners and repair shops, making it a valuable asset in the automotive industry’s quest for efficiency and responsibility.